Route Optimization: What It Is & How to Succeed in 2026

Author:

Divya Murugan

Published On:

Dec 10, 2025

1 min read

Before route optimization became mainstream, most forwarders handled orders in the simplest way possible. They assigned a vehicle, loaded the goods, and followed the stops in whatever sequence seemed convenient. For example, a driver might go A → C → D → B simply because those locations looked close on the map. The shipment still reaches every point, but is this the best strategy? Absolutely not.

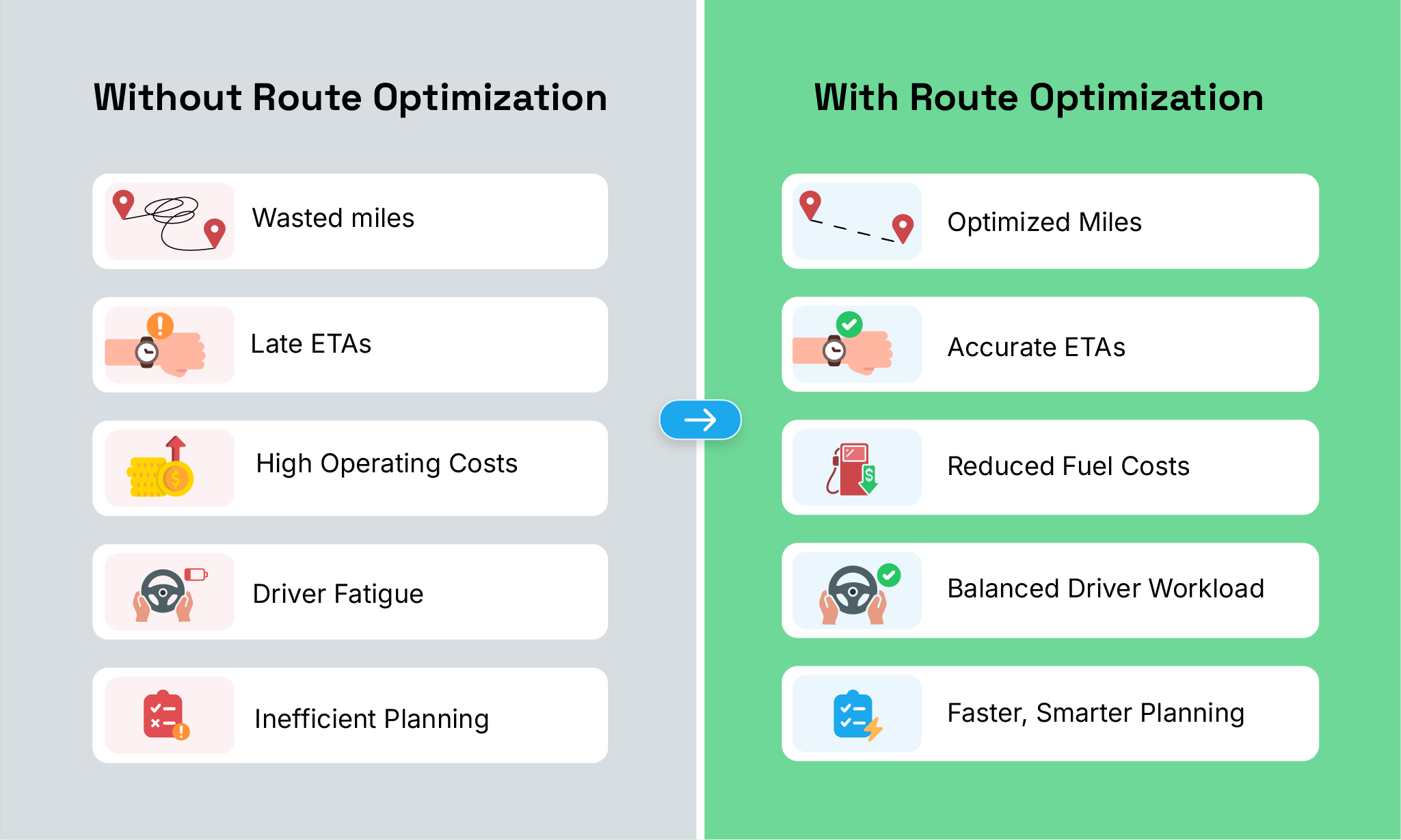

This old method leads to unnecessary detours, longer transit times, higher fuel usage, and, in some cases, delays that create penalties or demurrage when containers sit idle longer than expected. The delivery process is the same, but the way we optimize routes is completely different. Modern routing turns the same A B C D sequence into the most efficient order, reduces wasted miles, and prevents bottlenecks that affect your margins.

In short, route optimization isn’t just a tool; it’s the difference between steady, predictable operations and constant firefighting. Below, I’ll walk you through the problem, why it matters (the pain), and a practical roadmap for how you can succeed in 2026, with real examples, quick wins, and future-ready thinking.

What is Route Optimization?

For a modern freight forwarder, optimization means far more than finding the shortest path. It means seamless customs integration across multiple regulatory zones, automated carrier tendering, and ensuring full compliance while reducing dwell time wherever possible.

Route optimization is the process of choosing the best sequence of stops and the best paths between them based on time, cost, and operational constraints. These constraints include time windows, vehicle capacity, driver shifts, delivery priorities, and even EV battery levels. Instead of just picking the shortest route on a map, optimization uses clean data and intelligent rules to build routes that are realistic, predictable, and efficient.

In simple words, it brings together real-world data, business rules, and advanced calculations to turn scattered deliveries into a smooth and consistent workflow. When done right, it cuts wasted miles, avoids unnecessary delays, and keeps both drivers and customers aligned throughout the day.

Why Your Routes Are Costing You and the Fix You Need

Problem: Your drivers are wasting miles, customers are getting late ETAs, and your operations team is always two steps behind real-world surprises.

Agitate: That wasted time leaks margin, frustrates teams, and costs goodwill. Think more fuel, more overtime, lower driver morale, and a pile of customer support tickets every evening. I’ve seen dispatchers lose sleep mapping routes in spreadsheets while the clock runs out on delivery windows.

Solve: Modern route optimization, powered by AI, predictive analytics, and live data, replaces guesswork with adaptive routing that learns and improves. It reduces unnecessary miles, improves ETAs, and keeps drivers and customers calmer. Below’s how to get there in 2026.

Why it matters in 2026

In 2026, the logistics market is more competitive than ever. Getting quality leads is tough, and even after securing shipments, many forwarders feel the final profit is not satisfying when compared to the effort behind each move. One major reason is that many teams still do not focus on proper route optimization.

If you are operating in 2026 without route optimization, you are already losing margins without realizing it. Optimized routing cuts unnecessary miles, saves fuel, and reduces vehicle usage. Case studies consistently show savings of 20 to 40 % in total mileage, and in one community delivery drive, the switch to optimized routing brought down miles by nearly 37%, which allowed the team to operate with far fewer vehicles.

Route optimization is no longer a nice-to-have improvement. It is one of the strongest levers for protecting profit, especially when customer acquisition costs and operational pressure continue to rise.

Beyond cost: AI-driven routing slashes manual planning time and reduces customer support load, with some operators reporting large drops in support inquiries once ETAs and tracking became reliable. Industry coverage also shows major players investing in predictive routing and real-time decisioning as last-mile costs continue to make up a big share of logistics spend.

How Route Optimization Works in 2026

Think of modern route optimization like a smart conductor for your entire delivery symphony. It combines:

Algorithms that solve multi-stop, multi-vehicle puzzles (VRP, TSP variants).

Real-time data — traffic, weather, incidents, and driver locations.

Predictive analytics that forecast congestion and demand.

Constraints & business rules: time windows, capacity, driver skills, EV charge.

Human-in-the-loop workflows so dispatchers can inspect and tweak routes.

The result: routes planned with an eye to reality, continuously adjusted as the day unfolds.

The 3-Minute Routing Transformation

A small non-profit used to spend four hours planning delivery routes for a food drive. After they uploaded addresses into an optimizer, planning took three minutes, and they drove 37% fewer miles, using eight fewer vehicles. That’s the kind of operational transformation that turns volunteer chaos into a lean, predictable operation.

Lesson: You don’t need a 10,000-vehicle fleet to feel the benefits. The same algorithmic advantage scales down to teams of 2–10 vehicles.

9 Practical Steps to Implement Route Optimization

Clean your data first

Micro-story: I once routed a driver to “The Mall,” which existed twice in the city. A quick address-cleanup saved two missed deliveries. Bad data will undermine any optimizer.

Start small, measure fast

Run a two-week pilot with a subset of zones. Measure distance, on-time rate, and driver feedback.

Pick an AI-capable tool (but don’t outsource your thinking).

Look for predictive traffic handling, EV-aware routing, and easy integration with your order and warehouse systems.

Codify business rules

Priority customers, no-go streets, maximum stops per route, capture these as constraints so the optimizer respects real operations.

Enable real-time reoptimization

Accept that things change. Live traffic, cancellations, and new high-priority orders should trigger quick route adjustments.

Balance for fairness, not just math

If one driver always gets the long routes, morale dips. Use balancing settings — by time, stops, or workload — to keep assignments fair.

Make the driver app delightful

Drivers need clear instructions, quick navigation handoffs, and an easy way to mark exceptions. Friction here kills adoption.

Optimize for sustainability when possible

Collapse delivery density, avoid rush-hour legs, and favor low-emission routes if that aligns with your strategy.

Measure, learn, iterate

Weekly KPI reviews (fuel per delivery, ETA accuracy, driver hours) let you refine rules and retrain predictive models.

Common Challenges & How to Overcome Them

The algorithm gave weird-looking routes. That’s usually missing constraints or dirty data. Fix the inputs, adjust clustering rules, and involve dispatchers to teach the system what “practical” looks like.

Driver resistance to change. Include drivers early, collect feedback, and give time for territory familiarity to build. Drivers are happier when they see improvements in their day.

EV routing headaches. Factor battery state, charging time, and station availability into constraints, and simulate runs before committing real routes.

Integrations that stall. Start with CSV imports if APIs aren’t ready. Move toward deeper integration once the value is proven.

How Operations Change Before and After Route Optimization

Before Route Optimization | After Route Optimization |

Routes planned on manual spreadsheets | Plans generated automatically with an optimizer |

Hours spent adjusting stops and editing sequences | Planning time reduced to a few minutes |

Drivers start late and finish late | Drivers finish earlier with balanced workloads |

Frequent calls between dispatchers and drivers | Clear mobile app instructions and fewer support calls |

ETAs are often inaccurate | Customers receive accurate, real-time ETAs |

High fuel consumption due to unnecessary miles | Reduced fuel usage and shorter routes |

Dispatchers stressed with constant changes | Ops team finally gets breathing space |

Hard to scale during peak demand | Scalable, predictable, and more organized operations |

Inefficient workflows that hurt profit | Improved customer experience and lower overall costs |

Major Trends to Watch in 2026

AI-powered predictive routing - plans routes with likely future congestion in mind, not just current traffic.

EV-aware optimization - routes that schedule charging and protect delivery SLAs.

Sustainability-first routing - optimizing for emissions as a core metric.

Multi-modal & micro-fulfilment integration - blending vans, bikes, lockers, and micro-hubs.

These trends aren’t headlines; they are operational requirements for fleets that want to stay competitive.

Quick Checklist: What to Ask Your Route Optimization Vendor

Can the system re-optimize routes in real time?

Does it support EV constraints and charging stops?

How does it handle driver familiarity/territories?

What KPIs and reports are available out of the box?

What SLAs, reliability, and data privacy guarantees do you get?

Conclusion

Tech is only as good as the people using it. Use AI and automation to augment your dispatchers and drivers, not replace their judgment. Start with a small, measurable pilot, keep human oversight in place, and iterate based on real operational feedback.

If you commit to cleaner data, simple pilots, and a continuous feedback loop between ops and tech, 2026 can be the year your delivery operations stop surviving and start scaling, efficiently, sustainably, and with much less stress.

Frequently Asked Questions (FAQ)

What is real-time route optimization?

Real-time route optimization means the system automatically adjusts routes during the day based on traffic, new orders, cancellations, driver locations and unexpected delays. It keeps routes accurate and prevents late deliveries even when things change suddenly.

What is the difference between static and dynamic routing?

Static routing is planned once at the start of the day and stays fixed. Dynamic routing updates as new information comes in. Dynamic routing is more efficient for unpredictable operations because it adapts to real-world changes like traffic and urgent orders.

Will route optimization work for a team of 3 vehicles?

Yes. Even small fleets see measurable gains — fewer miles, fewer late deliveries, and less planner time.

Do I need AI for route optimization?

For dynamic, real-time, or large-scale routing, AI and predictive analytics are highly valuable. For tiny, static jobs, simpler tools can suffice.

How fast will I see ROI?

Many operators observe lower fuel and time costs within weeks of a pilot, especially where manual planning was the norm.

Don't forget to share this blog!