Top 10 Warehouse Management Software (WMS) for Logistics in 2025

Author:

Aashinya

Published On:

Nov 28, 2025

1 min read

Warehouse management is not just about storing and moving goods. It involves precise coordination and control to avoid errors. One slow scan, a misplaced pallet, or an outdated system can disrupt the entire supply chain and impact customer satisfaction.

Are you searching for the best warehouse management software (WMS) that can transform your logistics operations and streamline your business? The right warehouse management software integrates seamlessly with logistics systems to provide real-time shipment tracking, optimize inventory control, and enhance overall freight operations. The blog lists some of the top warehouse management software to help you choose the one that best fits your business needs.

Key Takeaways

Warehouse management software improves operational efficiency and accuracy by automating inventory tracking, order processing, and shipping within warehouses.

Integration with AI and blockchain technologies is transforming WMS, enabling predictive analytics for inventory optimization and secure, transparent supply chain transactions.

Selecting the right WMS involves understanding your unique warehouse challenges and ensuring seamless integration with existing logistics and supply chain management systems.

What is Warehouse Management Software?

A warehouse management software (WMS) is a digital system designed to manage all the processes of the warehouse. It controls, optimizes, and manages the day-to-day activities of the inventory. Additionally, it also helps teams track all inbound and outbound stocks, storage locations, barcode scanning, and ensures accurate order fulfillment.

Automating the processes of warehouse management improves operational efficiency, allowing businesses to focus on strategic activities. Additionally, warehouse management software can integrate with technologies like RFID (Radio Frequency Identification), barcode scanners, and transportation management software for better data sharing and coordination across the supply chain.

There are three main types of warehouse management software. The types are listed below.

Standalone WMS: Independent software that manages only the warehouse operations. It requires significant upfront investment but allows for extensive customization and data control.

Cloud-based WMS: Provides scalability and lower initial costs, making it ideal for businesses looking to adapt to changing market demands.

Supply Chain Execution Modules: It manages both warehouse and transportation systems. It also provides GTM (global trade management) support and simplifies the trade processes.

A better understanding of all the types helps in selecting the most suitable WMS for the business. Since a WMS plays a major role in the profitability of freight forwarding companies, it is suggested to choose the option that best suits the business size and operational requirement.

Top 10 Best Warehouse Management Software

1. CargoEZ

A modern, intuitive WMS built for businesses of all sizes with a powerful centralized warehouse dashboard. It ensures seamless warehouse visibility with real-time inventory tracking and smart allocation. CargoEZ WMS supports cross-docking, and goods can be categorized based on their storage requirements.

It also enables centralized order processing and prioritizing urgent order rules. Its smart warehouse layout mapping maximizes inventory space usage and optimizes slotting for faster pickups. It integrates effortlessly with the freight forwarding software and syncs shipments, bookings, and customer data for smooth operational flow. CargoEZ provides both mobile and desktop accessibility without requiring any hardware installation, making it suitable for businesses of any scale.

The WMS also enhances accuracy with QR-enabled scanning, which minimizes manual entry errors. Batch and serial number tracking ensure precise handling of the category of goods. For instance, if the goods are perishable, they will be placed in the food category and kept away from chemical or hazardous goods. CargoEZ's WMS is designed for adaptability, allowing businesses to expand warehouse locations and add new users. Additionally, the cloud-based architecture ensures fast deployment and secure data access.

2. Infor Warehouse Management Systems

The WMS provides management and inventory visibility and operational tracking. Additionally, it provides tools for routine warehouse activities like stock control, order picking, and reporting. The system supports integration and helps maintain day-to-day warehouse operations with moderate scalability.

Recommended for:

Large-scale manufacturers and distributors who require a WMS capable of basic integrations and standard inventory and operational tracking.

Possible limitations:

It may not be the best fit for small and mid-sized businesses due to its complexity and scalability level.

3. Oracle Warehouse Management Software

Oracle warehouse management software provides standard execution tools to track inventory visibility and supports multi-location operations. It provides integration only within the Oracle ecosystem. Apart from these, it also supports barcode scanning and item-level tracking.

Recommended for:

Organizations that operate within the Oracle ecosystem or have multi-location warehouse setups.

Possible limitations:

It might require a higher level of configuration and technical involvement.

4. Blue Yonder’s AI-driven platform

Blue Yonder's warehouse management system is designed to support day-to-day warehouse operations. It provides features such as inventory visibility, order fulfillment, and labor planning. Additionally, it supports multi-location operations and provides basic real-time visibility of stock movement.

Recommended for:

Organizations with structured warehouse processes that can accommodate a more involved configuration and setup.

Possible limitations:

May require additional implementation support, and the configuration process can be more extensive.

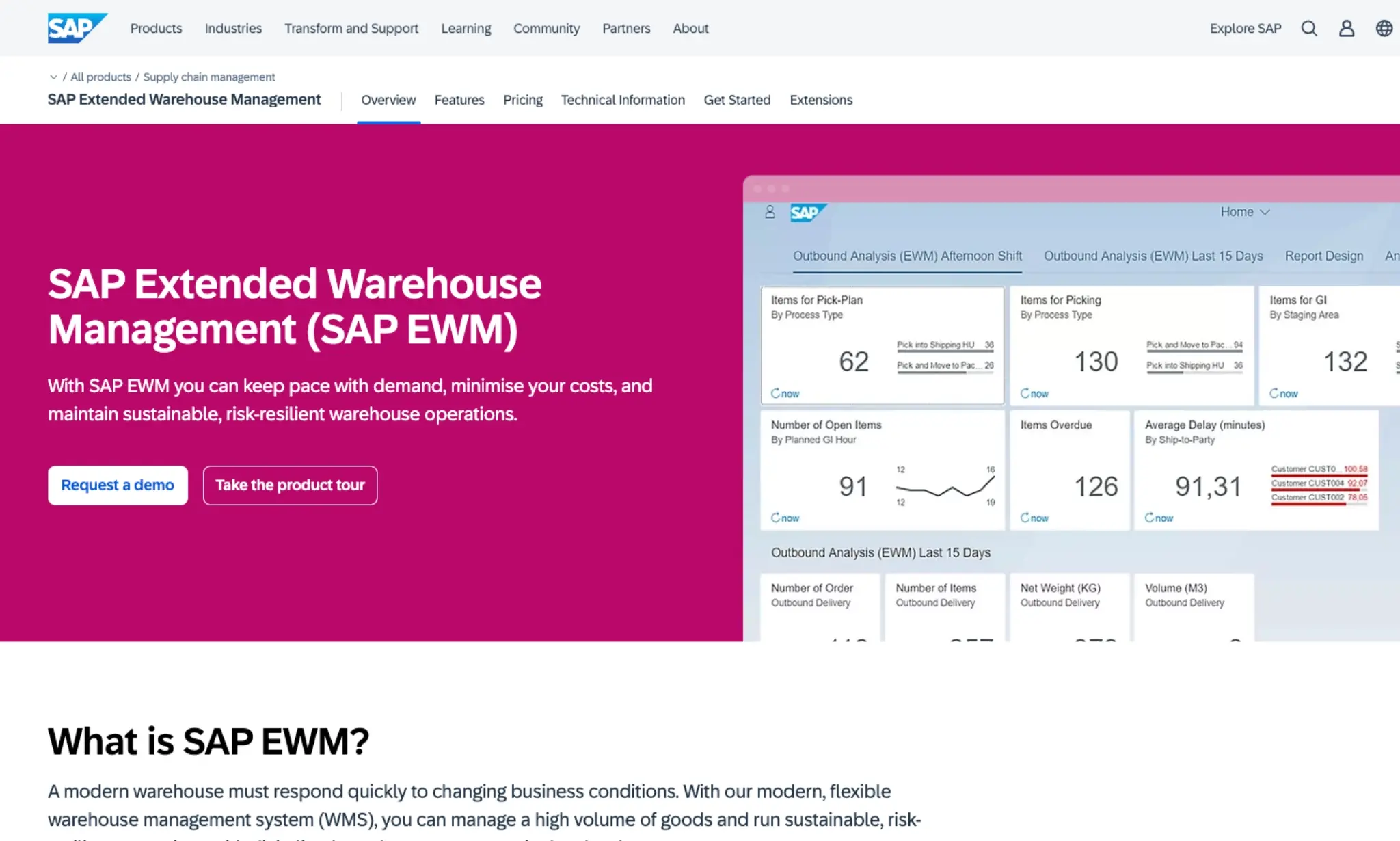

5. SAP Extended Warehouse Management:

It is designed to manage complex warehouse operations. It provides tools like inventory visibility, resource and workflow management. It also provides real-time tracking of the goods movement and slotting.

Recommended for:

Organizations with complex warehouse workflows.

Possible limitations:

Maybe resource-intensive and requires internal expertise for configuration and ongoing workflow management.

6. Manhattan Active Warehouse Management

The system provides tools for various warehouse operations like slotting, labor management and order processing. It is flexible and provides real-time warehouse data to support decision-making.

Recommended for:

Suitable for organizations with structured warehouse operations and with complex workflows.

Possible limitations:

It may be complex for small or mid-scale logistics operations.

7. Tecsys’s Elite Warehouse Management:

Tecsys WMS provides tools for warehouse operations such as inventory control, order fulfillment, and labor optimization. It also provides real-time visibility across warehouse activities, supporting decision-making and process coordination.

Recommended for:

Organizations with established warehouse processes and the resources to manage a more detailed setup.

Possible limitations:

It may require additional time and resources, making it less suitable for smaller logistics teams.

8. Shipsy’s Stockone WMS:

It provides essential tools for real-time stock updates and helps streamline basic warehouse processes with dashboards and automated alerts. Additionally, it also focuses on improving operations and supports integration with logistics workflows.

Recommended for:

Organizations with small to mid-sized warehouse operations seeking basic process automation and integration support.

Possible limitations:

May need extra configuration for complex operations, and scaling to larger or multi-location setups could be less intuitive.

9. SnapFulfil by Synergy Logistics

SnapFulfil is the cloud-based warehouse management system developed by Synergy Logistics. Apart from inventory control, order processing, it also provides warehouse task management. It supports rules-based workflows and provides real-time monitoring of picking, packing, and replenishment activities.

Recommended for:

Organizations with standard warehouse processes, with cloud-based task management and workflow visibility.

Possible limitations:

Customization may be limited for highly unique warehouse processes, and implementation timelines could be longer for organizations with more complex requirements.

10. Increff

Increff provides efficient order management and cross doc services. It also provides real-time stock visibility and helps manage warehouse operations. It is scalable and the platform provides seamless automation. However, the system may not be suitable for all businesses with a multi-modal workflow.

Recommended for:

Organizations with scalable warehouse operations with automated order management and stock visibility.

Possible limitations:

May not fully support businesses with complex multi-modal workflows.

How to Choose the Right WMS for Your Business

There are several factors to consider when choosing a warehouse management system, and some of them are listed below.

Identify your specific warehouse management challenges.

Understand your operation’s unique needs to pinpoint essential features.

Focus on features such as real-time inventory tracking and order management, which are crucial for streamlining your software selection process.

After evaluating the factors, now, evaluate the total costs of different WMS options against the anticipated returns to understand the potential ROI.

Also, consider the integration capabilities with your existing systems to streamline seamless data flow across your operations to save time.

Implementation Process

Successful implementation of warehouse management software requires careful planning and execution. Begin with a thorough assessment of your existing systems to identify workflow bottlenecks and integration blind spots. Gathering detailed requirements from stakeholders helps set clear goals for the implementation.

Comprehensive training programs for employees are necessary to ensure smooth adoption of the new software system. Continuous monitoring of the software’s performance is important to identify areas for improvement and ensure it meets evolving business needs.

Conclusion

Effective warehouse management software like CargoEZ can significantly boost operational efficiency, customer satisfaction, and business growth. Although software solutions automate routine tasks, human expertise is crucial for navigating the complexities of international trade. Integrating streamlined software tools allows freight forwarders to focus on higher-value tasks, enhancing service quality and client satisfaction.

Frequently Asked Questions (FAQs)

1. How does WMS improve warehouse operations?

WMS automates routine tasks, reduces manual errors, provides real-time inventory visibility, and optimizes space utilization, leading to increased efficiency and accuracy in warehouse activities.

2. Can WMS integrate with freight forwarding software?

Yes, many WMS solutions seamlessly integrate with freight forwarding software to streamline the entire shipping process, enhance shipment tracking, and improve logistics operations.

3. What types of WMS are available?

The types of WMS available are cloud-based, stand-alone, and supply chain execution modules that combine warehouse and transportation management functionalities.

4. Is cloud-based WMS better than standalone WMS?

Cloud-based WMS provides scalability, lower upfront costs, and remote accessibility, making it suitable for many businesses. Standalone WMS may provide more customization but often requires a higher initial investment.

5. Does WMS support real-time inventory tracking?

Yes, most modern WMS solutions provide real-time inventory tracking using technologies like RFID and barcode scanning.

Don't forget to share this blog!