Warehouse Management Software Benefits: How Modern WMS Transforms Today’s Warehouses

Author:

Dharshini Balamurugan

Published On:

Jan 13, 2026

1 min read

Warehousing has always been at the heart of global supply chains. It’s where products live, where accuracy matters most, and where one mistake can ripple across procurement, inventory, logistics, sales, and customer experience.

But if there’s one thing that defines the modern warehouse, it’s this:

Warehouses are no longer simple storage spaces, they are strategic hubs.

And the software that manages them can make or break operational efficiency.

As customer expectations rise, order volumes fluctuate, and supply chains grow more complex, traditional warehouse processes are struggling to keep up. Spreadsheets, paper trails, manual picking lists, and siloed systems simply weren’t built for today’s speed, scale, or visibility demands.

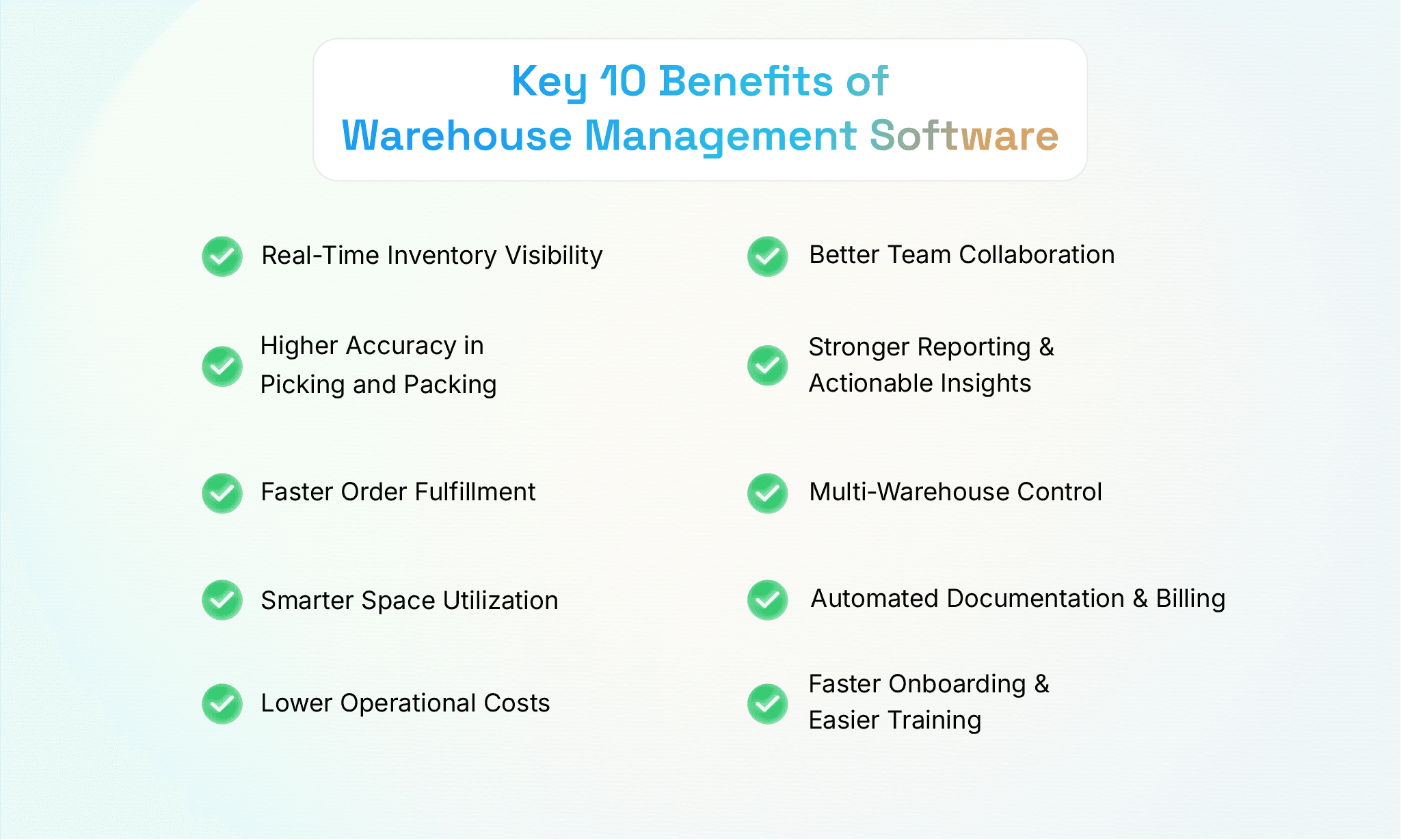

Key 10 Benefits of Warehouse Management Software

Warehouse management software isn’t just about organization, it’s about results. Beyond features and dashboards, WMS delivers real operational impact. Whether you manage one warehouse or many, these capabilities are what make modern warehousing efficient, predictable, and scalable

1. Real-Time Inventory Visibility

Imagine knowing, at any moment, exactly how much inventory you have, where it’s stored, what’s available, and what needs attention. A WMS provides live visibility into stock levels, locations, and movement, eliminating guesswork. This clarity helps prevent stockouts, overstocking, lost items, and manual counting errors, one of the biggest reasons warehouses adopt WMS in the first place. Companies using WMS report up to 99% inventory accuracy and a 20–30% reduction in stockouts.

2. Higher Accuracy in Picking and Packing

Picking and packing errors are costly, not just financially, but in customer trust. A WMS guides warehouse staff through each task, matches orders to inventory automatically, and ensures FIFO (First In, First Out) and FEFO (First Expired, First Out) compliance. WMS adoption reduces picking errors by 20–40%, and combined with FIFO/FEFO compliance, ensures products are shipped in the right order, reducing returns and complaints. The result is fewer mistakes, cleaner dispatches, and consistently accurate orders that improve customer satisfaction.

3. Faster Order Fulfillment

Speed is a competitive advantage, and WMS plays a direct role in achieving it. By optimizing picking routes, automating workflows, and assigning tasks in real time, warehouses can move orders faster without sacrificing accuracy. Businesses using WMS see 30–50% faster order processing times, enabling quicker dispatch and improved customer satisfaction. Clear coordination between warehouse and transport teams ensures shipments go out on time, every time.

4. Smarter Space Utilization

Warehouse space is valuable, and a WMS helps make the most of it. By intelligently assigning SKUs to the right racks or zones and reducing dead stock, the system improves movement flow and minimizes congestion. Smarter placement means faster picking, safer operations, and better use of every square foot. Optimized slotting and zoning can increase warehouse storage efficiency by 10–25%, reducing congestion and speeding up picking.

5. Lower Operational Costs

Every inefficiency in a warehouse comes with a cost. A good WMS reduces reliance on manual labor, cuts down rework caused by errors, minimizes inventory losses, and eliminates paper-heavy processes. Furthermore, seamless warehouse integration with existing ERP or accounting systems prevents the need for double data entry and reduces administrative overhead. Over time, these improvements translate into significant savings across operations.

6. Stronger Reporting and Actionable Insights

A WMS turns operational data into meaningful insights. From live performance metrics and SKU aging reports to staff productivity and space utilization, dashboards provide a clear picture of what’s working and what isn’t. Better visibility into data leads to smarter decisions and continuous improvement.

7. Better Team Collaboration

With everything centralized in one system, teams no longer rely on scattered messages, handwritten notes, or assumptions. A WMS keeps assignments, workflows, inventory status, and documentation in one place, ensuring everyone operates on the same information, instantly and accurately.

8. Multi-Warehouse Control

As businesses grow, managing multiple warehouses becomes increasingly complex. Companies managing multiple locations with WMS achieve 20–35% faster inventory reconciliation across sites. A strong WMS allows teams to standardize processes, compare performance across locations, control access by site, and monitor inventory across all warehouses in real time. Scaling operations becomes structured and manageable, not chaotic.

9. Faster Onboarding and Easier Training

Warehouses often depend on seasonal or temporary workers, and long training cycles slow everything down. Modern WMS platforms are intuitive, mobile-friendly, and easy to learn, helping new hires get productive quickly while reducing onboarding time and training costs.

10. Automated Documentation and Billing

Often overlooked, documentation and billing automation is a major advantage of WMS. From generating invoices and applying storage charges to printing labels and managing charge cycles, the system streamlines financial workflows. The best warehouse management software solutions recognize that efficiency shouldn't stop at the loading dock; by automating the back-office tie-ins, these platforms benefit finance teams just as much as warehouse operations, improving accuracy and speed across the board.

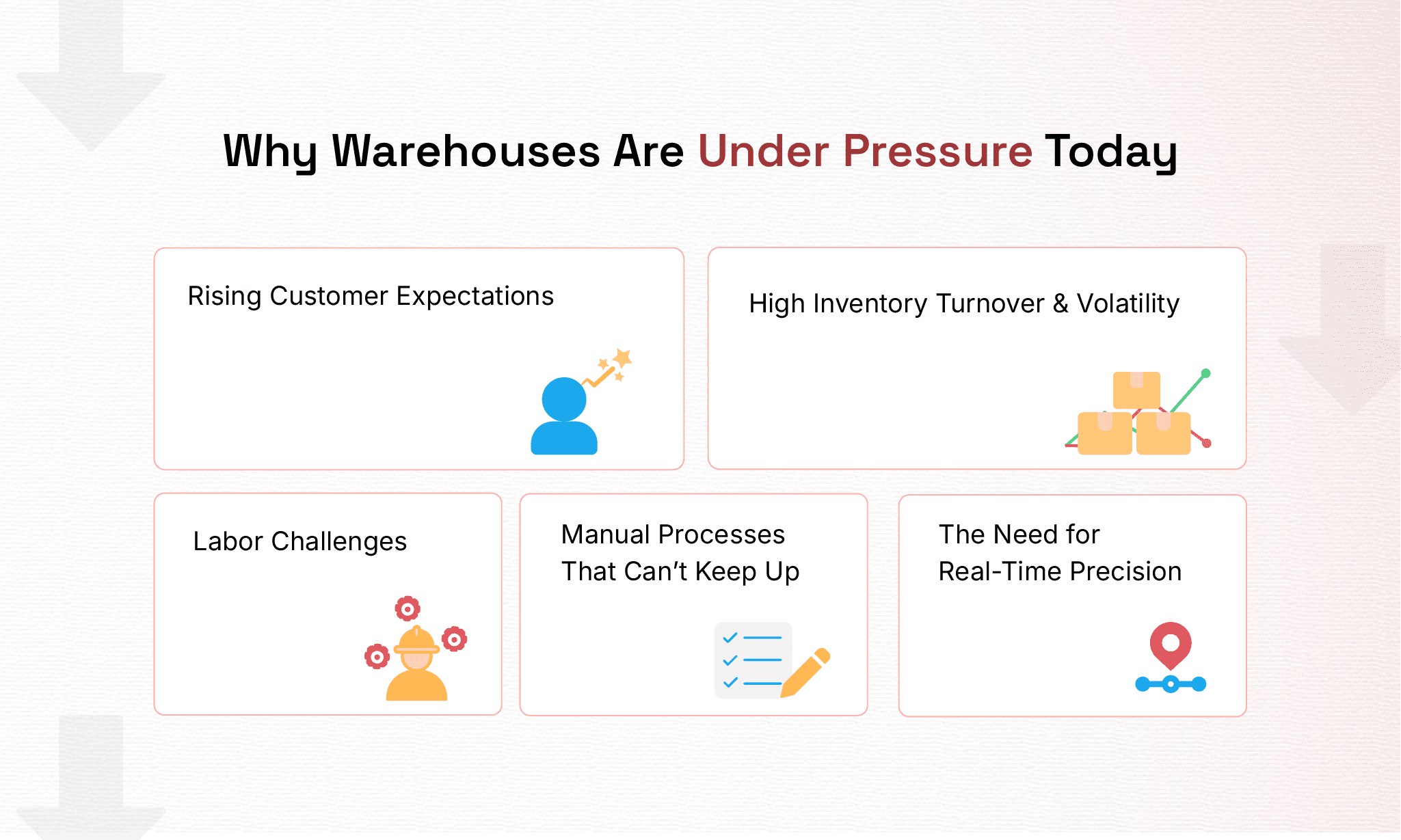

Why Warehouses Are Under Pressure Today

Warehousing has always been complex, but the last decade has transformed it completely. Faster supply chains, rising customer expectations, and operational pressure have accelerated the need for smarter, more connected warehouse systems.

1.1 Rising Customer Expectations

Customers today expect next-day delivery, faster fulfillment, real-time updates, and error-free orders as the standard—not the exception. This shift isn’t limited to e-commerce. Even B2B customers now demand Amazon-level visibility into where their inventory is and when it will arrive. Warehouses that fail to meet these expectations risk delays, dissatisfaction, and lost trust.

1.2 High Inventory Turnover and Volatility

Seasonal demand spikes, supply shortages, and unpredictable buying patterns make inventory planning extremely challenging. Without real-time data, warehouses struggle to respond quickly, leading to stockouts, overstocking, or missed opportunities. To stay competitive, warehouses must adapt fast and make decisions based on live inventory insights.

1.3 Labor Challenges

Warehouses across the globe are facing high employee turnover, rising labor costs, skill gaps, and longer onboarding times. Training new staff on manual or outdated systems slows operations and increases errors. Without automation and clear workflows, productivity drops and teams become overwhelmed.

1.4 Manual Processes That Can’t Keep Up

Many warehouses still rely on telephonic updates, paper pick lists, Excel sheets, manual counting, and disconnected software systems. These outdated processes slow down operations, create data silos, increase errors, and make real-time visibility nearly impossible—especially as order volumes grow.

1.5 The Need for Real-Time Precision

Modern businesses need instant clarity on what’s in stock, where it’s stored, what’s ready to ship, what’s delayed, what’s trending, and where bottlenecks are forming. Real-time visibility is no longer a nice-to-have, it’s foundational to running an efficient warehouse.

This is exactly where warehouse management software comes in—bringing visibility, automation, and control to today’s fast-moving warehouse operations.

Traditional vs. Modern WMS: What’s the Difference?

Warehouses today are steadily moving away from legacy systems toward modern, cloud-based warehouse management solutions and for good reason. Traditional WMS platforms are usually installed on local servers, making them expensive to maintain and difficult to scale. They often come with limited integration capabilities, static reports, and rigid workflows. Add to that the lack of mobile support and complex interfaces, and onboarding new staff becomes time-consuming and inefficient.

Modern cloud-based WMS solutions, on the other hand, are built for flexibility and speed. They can be accessed anytime, from anywhere, and update automatically without manual intervention. These systems scale effortlessly as business volumes grow and are designed to work seamlessly on mobile devices and tablets—right on the warehouse floor. With real-time dashboards, live inventory insights, and smooth integrations with ERP, accounting, and logistics systems, cloud WMS platforms make managing multiple warehouses simpler and far more efficient.

Simply put, modern WMS solutions are designed for today’s supply chains—fast, mobile, connected, and visibility-driven, making them essential for warehouses that want to stay competitive.

Why WMS is Becoming a Competitive Differentiator

For most companies, warehouse operations used to be back-end processes.

But today?

Customer expectations tie directly to warehouse speed

Profitability depends on accuracy and cost control

Logistics depends on visibility

Growth depends on scalability

A company with a smart WMS simply outperforms those without one.

The difference is obvious in:

Fulfillment accuracy

Delivery timelines

Cost efficiency

Customer retention

Operational reliability

Data-driven decisions

Warehouses aren’t just fulfilling orders, they’re shaping the entire customer experience.

How to Choose the Right Warehouse Management Software

Not all warehouse management systems are created equal. Choosing the right WMS can directly impact efficiency, scalability, and long-term operational success. Here are the key factors businesses should evaluate before making a decision.

Cloud vs. On-Premise Deployment

Cloud-based WMS solutions are faster to implement, more cost-effective, and far easier to scale than on-premise systems. They eliminate heavy infrastructure costs and allow teams to access the system from anywhere, without relying on local servers.

Ease of Use and Adoption

A WMS is only effective if teams actually use it. Complicated interfaces slow adoption, increase training time, and frustrate staff. An intuitive, user-friendly system ensures faster onboarding and smoother day-to-day operations.

Integration Capability

A strong WMS must seamlessly connect with other business systems such as TMS, ERP, accounting software, order management tools, inventory systems, and freight management platforms. Integration eliminates data silos and ensures consistent, real-time information across the organization.

Scalability for Future Growth

Warehouses evolve as businesses grow. The right WMS should handle increasing order volumes, additional locations, and more complex workflows without requiring major system changes or replacements.

Mobility on the Warehouse Floor

Modern warehouse operations demand mobility. A WMS should support tablets and mobile devices, allowing teams to perform tasks directly on the floor without relying on fixed workstations or paper-based processes.

Real-Time Dashboards and Visibility

Visibility is the foundation of efficient warehousing. Real-time dashboards help managers track inventory, performance, bottlenecks, and exceptions instantly, enabling faster and better-informed decisions.

Automation Capabilities

Automation reduces dependency on manual work and minimizes errors. From task assignments and picking workflows to documentation and billing, automation helps warehouses move faster while maintaining accuracy.

Multi-Warehouse Support

For growing businesses, managing multiple warehouses is non-negotiable. A capable WMS should support centralized control, standardized processes, and real-time visibility across all locations, without added complexity.

The Future of Warehousing: Smarter, Faster, Data-Driven

Future-ready warehouses will look very different from what we’ve known in the past. They will be highly automated, fully visible, and driven by exceptions rather than constant manual oversight. Instead of relying heavily on human intervention, these warehouses will operate through intelligent systems that guide decisions, streamline workflows, and eliminate inefficiencies. Mobility will be built in, allowing teams to work seamlessly from anywhere on the warehouse floor, while overall operations become faster, leaner, and far more efficient.

In this shift, warehouse management software will become the default operational backbone. Companies that adopt WMS early gain a clear advantage—they operate faster, spend less on avoidable inefficiencies, scale without chaos, and consistently outperform competitors still relying on manual processes. As supply chains continue to evolve, warehouses will not return to spreadsheets, paper trails, or disconnected systems.

The future of warehousing is digital, data-driven, and software-led. Today, WMS isn’t just a tool, it’s the central nervous system of warehouse success.

Where CargoEZ WMS Fits Into the Modern Warehouse

All of this brings us to platforms like CargoEZ WMS, designed specifically for today’s warehousing challenges.

CargoEZ WMS combines:

Real-time inventory tracking

Accurate picking & packing

Centralized multi-location management

Automated invoicing & storage charges

Cloud accessibility

Simple user experience

Mobile floor operations

Smart dashboards & insights

It’s built to turn warehouse complexity into clarity.

What CargoEZ WMS Delivers:

Know What’s Where: Every SKU, rack, and zone tracked in real time

Error-Free Fulfillment: Streamlined picking and dispatch

One Platform for All Warehouses

Analytics That Drive Growth

Zero Paperwork Chaos: Labels, invoices, storage charges—all automated

Cloud Access Anywhere

Quick onboarding for new staff

For businesses looking for a modern, intuitive WMS that doesn’t overwhelm teams, CargoEZ WMS is a strong, future-ready choice.

Conclusion

Warehouse management software isn’t just another operational tool, it’s a transformation engine. It brings clarity to inventory, control to workflows, speed to fulfillment, accuracy to every task, and the scalability needed to grow without friction. Most importantly, it adds intelligence to warehouse operations, turning data into decisions instead of guesswork.

Whether you’re managing a small, single-location warehouse or overseeing a global, multi-site operation, WMS plays a defining role in how efficiently you operate and how fast you can scale. As customer expectations continue to rise and supply chains grow more complex, the warehouses that embrace smarter systems will be the ones that stay competitive—and win.

When the time comes to modernize, eliminate manual chaos, and gain complete operational control, platforms like CargoEZ deliver the visibility and automation needed to run a smarter, faster, and more resilient warehouse.

Frequently Asked Questions (FAQs)

1. What is warehouse management software (WMS)?

Warehouse management software is a digital system that helps businesses manage day-to-day warehouse operations such as inventory tracking, picking, packing, storage, shipping, and reporting. A modern WMS provides real-time visibility, automation, and control across warehouse workflows.

2. Who needs a warehouse management system?

Any business that stores, moves, or ships inventory can benefit from a WMS. This includes manufacturers, distributors, 3PLs, e-commerce companies, retailers, and businesses managing multiple warehouses or high order volumes.

3. What are the main benefits of warehouse management software?

The biggest benefits include real-time inventory visibility, higher picking accuracy, faster order fulfillment, better space utilization, reduced operational costs, improved reporting, easier scaling, and stronger customer satisfaction.

4. How does WMS improve inventory accuracy?

A WMS tracks inventory movements in real time across racks, zones, and locations. By reducing manual entries and automating updates, it minimizes counting errors, prevents lost stock, and ensures inventory records match physical inventory.

5. What is the difference between FIFO and FEFO in WMS?

FIFO (First In, First Out) ensures older stock is dispatched first, commonly used for general inventory.

FEFO (First Expired, First Out) prioritizes items with the earliest expiry dates, critical for food, pharmaceuticals, and perishable goods. A WMS automates both to reduce waste and ensure compliance.

6. Can a WMS handle multiple warehouses?

Yes. Modern WMS platforms are designed to manage multiple warehouses from a single system. They allow centralized visibility, standardized workflows, location-based access controls, and real-time inventory tracking across all sites.

7. Is cloud-based WMS better than on-premise WMS?

For most businesses, yes. Cloud-based WMS solutions are easier to deploy, more cost-effective, automatically updated, scalable, and accessible from anywhere. On-premise systems often require higher maintenance and limit flexibility.

8. How long does it take to implement a WMS?

Implementation timelines vary based on warehouse size and complexity, but modern cloud-based WMS solutions can often be implemented much faster than legacy systems—sometimes within weeks instead of months.

9. Does WMS reduce labor costs?

A WMS doesn’t replace teams, but it makes them significantly more productive. By optimizing workflows, reducing errors, and shortening training time, businesses often see lower labor costs per order and better output from existing staff.

10. How do I choose the right warehouse management software?

Look for a WMS that is cloud-based, easy to use, scalable, mobile-friendly, and integrates seamlessly with your ERP, TMS, accounting, and logistics systems. Real-time dashboards, automation, and multi-warehouse support are also key decision factors.

Don't forget to share this blog!